Introduction

One of the biggest issues facing the construction industry for many years has been the damage to reinforced concrete (RC) structures. The majority of the existing buildings are noncompliant with seismic regulations. These structures frequently display flaws like insufficient detailing, broken load paths, and inadequate capacity design considerations. That is further supported by the devastating earthquakes that continue to cause human injuries and deaths in addition to the structural collapse of buildings. Given that disastrous earthquakes can happen anywhere in the world at any time, it is becoming more and more important to help strengthen the existing structures. Although many rehabilitation programs take a lot of time and cause a lot of disturbance because of how difficult it is to apply them, they may not be cost-effective.

RC beams are repaired and strengthened using a variety of techniques. The most popular of these techniques is to steel jacket damaged or weak RC beams in order to repair and reinforce them. The drawbacks of this procedure, which is challenging, time-consuming, and laborious, include a large increase in the weight of the building, the need for additional foundation system arrangements, and the inability to use the structure while it is being strengthened. However, the above-mentioned drawbacks can be minimized by using Fibre Reinforced Polymers (FRPs) as a strengthening material. It is a composite material constructed from a polymer matrix and fibre reinforcement. The most popular fibres are carbon (C), glass (G), or aramid (A), and they are joined by an epoxy, vinyl ester, or polyester matrix. They were initially employed as an external retrofit in buildings in Europe and Japan, but there has been significant advancement in the last 15 years or so.

Carbon Fibre Reinforced Polymer

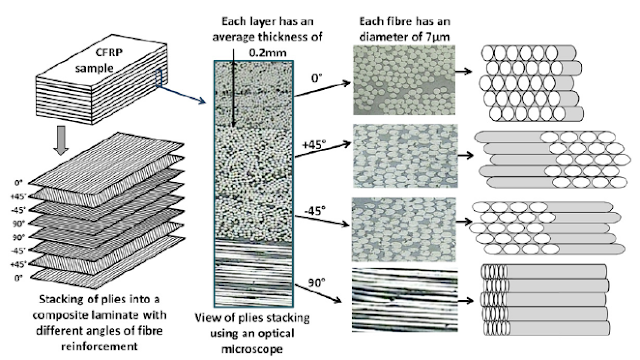

The atoms of carbon are linked together in form of crystals that are roughly parallel to the fibre's long axis to create carbon fibre, which has a high strength-to-volume ratio due to the crystal alignment (it is very strong for its size). To create a tow, which may be used on its own or woven into fabric, thousands of carbon fibres are packed together.

To create a composite, carbon fibres are typically mixed with other materials. It can be baked after being infiltrated with a plastic resin to create carbon-fibre-reinforced polymer, also called carbon fibre. Carbon fibre is very rigid, and has a very high strength-to-weight ratio, but is also relatively fragile.

Advantages:

The carbon-wrapped column reinforcing technology is the one that causes the least amount of disturbance to the structural components. Utilizing carbon fibre reinforced concrete or polymers in an efficient manner can considerably extend the life of the structure while also reducing the amount of maintenance that is required. Since the columns that are covered in carbon fibre are resistant to corrosion, they are utilised for corrosion control as well as the restoration of structures made of reinforced concrete. In addition, carbon fibre reinforced concrete and carbon wrapped columns are usually utilized in the construction industry to enhance concrete structures. One of these materials is carbon fibre, which, in order to create a composite, is typically combined with a number of other types of materials. Carbon fibres are one of the most widely used materials in the field of civil engineering due to the properties they possess, which include high levels of stiffness and tensile strength, low levels of weight and chemical resistance, and high levels of temperature tolerance, and low levels of thermal expansion. Its advantages include;

- Corrosion resistance

- Short construction period

- No maintenance required

- Increased flexural capacity of column, beam and slabs

- Hardening of structural member without significantly increasing its size

- Adds strength to concrete

- Increased load carrying capacity

- Minimal change to structure's shape and appearance

- Faster installation

- Portection from enviromental degradation

Disadvantages:

Some disadvantages of FRP include its difficulty to adhere to a wet surface, the resin's poor performance at temperatures over the glass-transition temperature, its poor fire resistance, and its lack of vapour permeability.

To increase the shear, flexural, and axial capacity of various reinforced concrete elements, such as columns, beams, slabs, walls etc., it can be applied. Epoxy resins must be utilized in the application to connect FRP to the exterior surfaces of structural components because it is typically used as an externally reinforcing material in the form of plates, sheets, or anchors.

1 Comments

Thanks for sharing, comes to choosing the best PPC cement in India, Amrit Cement stands out for its exceptional strength and durability. It offers superior performance in construction projects, ensuring long-lasting and reliable results.

ReplyDelete