The manufacturing of Portland Cement (Wet and Dry Process) comprises of complex process of mixing, heating in a cement kiln and grinding of raw materials i.e. Limestone and Clay which leads to Bouge Compounds formation. The Bouge compounds are actual responsible for properties of cements.

Cement is greenish grey colored fine powder. Cement become hard and strong when mixed with water. This property of cement make the cement a good building materials.

Cement is greenish grey colored fine powder. Cement become hard and strong when mixed with water. This property of cement make the cement a good building materials.

- The Cement is manufactured by mixing the calcareous component and argillaceous component by ratio of 3:1.

- The calcareous component can be limestone, chalk, marine shells, marl whereas the few examples of argillaceous components are shale, clay, blast furnace slag and slate.

- Lime is main source of extraction of calcareous component whereas argillaceous component consists of silica, alumina, iron oxide and other impurities.

- The cement is manufactured by two processes: Wet Process and Dry Process.

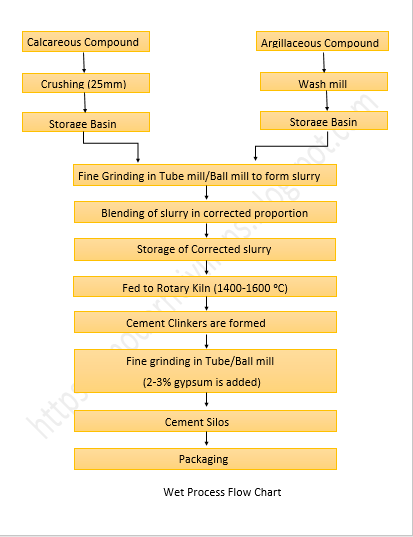

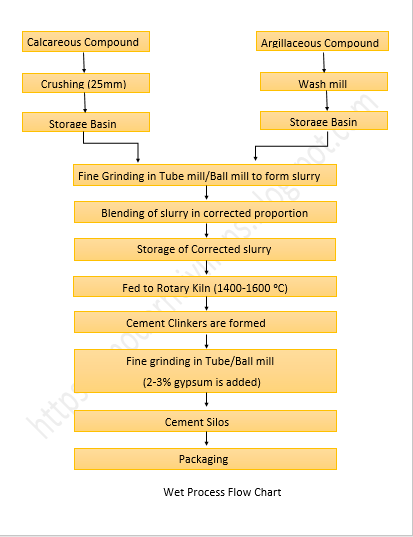

1.Wet Process:

- It is the old process of manufacturing which is no longer in use.

- It requires high degree of fuel consumption and power consumption which leads to increase the manufacturing cost.

- No preheater is required in this case.

2.Dry Process:

- It is a new method of manufacturing method in which fuel and power consumption has been reduced to larger extent.

- Preheating is done by Exhaust gas which help in reducing the manufacturing cost.

- Dry process is used majorly for manufacturing of cement.

Different zone in the process

1. Nodule Zone:

- The calcination of limestone occur in this zone. Limestone get disintegrated into two component- Lime and carbon dioxide.

- When CO2 is evaporated from the mix, the raw mix is converted into nodules.

2. Burning Zone:

- In this zone, integration of calcareous and argillaceous compounds i.e. lime, silica, alumina, iron oxide etc. get united with each other at a very high temperature and this process is called fusion.

- In this zone, the following reaction take place

2CaO + SiO2 Ca2SiO4 = C2S (Dicalcium Silicate)

3CaO + SiO2 Ca3SiO5 = C3S

(Tricalcium Silicate)

3CaO + Al2O3 Ca3Al2O6 =

C3A (Tricalcium Aluminate)

4CaO + Al2O3

+ Fe2O3 Ca4Al2Fe2O10

= C4AF (Tetra- Calcium Alumino- Ferrite)

The above

four compound obtained from rotary kiln are known as Bouge Compound.

3 Comments

How many employees does Vegas Casino have? - Wooricasinos

ReplyDeleteHow 바카라룰 many employees does Vegas Casino have? - 룰렛 게임 Las Vegas 마틴 배팅 casinos. Casino Name (Last Name): 먹튀폴리스 검증업체 The Casino Owner is: Nevada Gaming Control 슬롯가입머니 Board (NSB).

Thank you for clarifying the procedure. The dry process included improved techniques that reduced power consumption. Our Rotary Kiln Plant is also energy efficient and built with high-quality materials.

ReplyDeleteBest cement manufacturers

ReplyDeletecontribute to rural development in India by supplying high-quality materials. Their efforts improve infrastructure, create jobs, and support local economies.