The California Bearing Ratio (CBR) test is a penetration test to evaluate the strength of sub grade soil or other materials like base course under the carriageway. The CBR test is the measure of resistance to the penetration of flexible pavement material or soil under the effect of standard plunger under the standard conditions.

CBR (in %) = (load on specimen at 2.5 mm or 5 mm penetration)/(load on standard material at corresponding level)*100

The standard load value at specified penetration value have been established by a series of test on the standard specimen of aggregate and these value is given as following:

Penetration (in mm) Standard Load(in Kg) Unit Standard Load(in Kg/ sq.cm)

2.5 1370 70

5 2055 105

Transparent Concrete

Construction Waste Management

For Modified California Bearing Ratio Method for Design of Flexible Road as per IRC37, Click here.

It is developed by California State Highway Department before the world war second. California Bearing Ratio is defined as the ratio of load(or pressure) sustained by specimen at 2.5 or 5.0 mm penetration by the load(or pressure) sustained by standard specimen at standard conditions and corresponding penetration level. It is generally represented in percentage.CBR (in %) = (load on specimen at 2.5 mm or 5 mm penetration)/(load on standard material at corresponding level)*100

The standard load value at specified penetration value have been established by a series of test on the standard specimen of aggregate and these value is given as following:

Penetration (in mm) Standard Load(in Kg) Unit Standard Load(in Kg/ sq.cm)

2.5 1370 70

5 2055 105

Determination of CBR value in the laboratory

The CBR apparatus consist of a mould 150 mm diameter having base plate and collar, loading frame with a plunger in cylindrical shape of 50 mm diameter. A dial gauge is provided to measure the penetration value of the specimen. The CBR test can be performed on undisturbed soil sample or on remoulded soil. It can also performed on specimen in soak condition or in unsoak condition. As per IRC(Indian Road Congress) guidelines, the test should be carried out on remoulded specimen in soak conditions. Only the material which passes from 20 mm sieve should be used in these test.

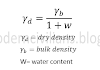

The specimen in the mould is compacted to maximum dry density at Optimum Moisture Content.

Then the specimen is subjected to soaking for four days, swelling and water absorption value should be noted down. Then the surcharge weight is placed on the top of specimen and whole assembly is placed under the the plunger of the loading frame. The load value corresponding to penetration value of 0.0, 0.5, 1.0, 1.5, 2.0, 2.5, 3.0, 4.0, 5.0, 7.5, 10.0, 12.5 mm is noted down and a graph between load value and its corresponding penetration value is plotted.

In the graph, there are two curves- upper curve with convexity upward and lower curve with initially concavity upward. These indicate that lower curve require necessary correction by establishing a tangent from the steepest point of lower curve. These reason behind initial concavity is:

- The top layer of specimen is too soft after soaking in the water.

- The top surface is uneven.

- The penetration plunger of the loading machine is not vertical.

Normally, the CBR value for 2.5 mm penetration is higher than CBR value for 5 mm penetration and higher value from both values is reported as CBR value of the material. If the value at 5 mm penetration is higher than the value for penetration of 2.5 mm, then the test is repeated for the check and if same result is obtained then report these value as CBR value of material.

The CBR test is an arbitrary strength test and hence these test cannot be used to calculate the soil properties like cohesion or shear resistance.

For Modified California Bearing Ratio Method for Design of Flexible Road as per IRC37, Click here.

You may also like:

Self Compacting ConcreteTransparent Concrete

Construction Waste Management

0 Comments